Features

Most Popular Types of Concrete Floor Finishes

Concrete finishes allow for an endless array of decorative options.

A concrete finish results from compressing, flattening, and polishing the surface of freshly poured concrete, yielding a smooth, attractive, and durable slab.

Known as concrete finishing, this procedure begins right after the concrete is poured, ensuring a seamless blend of form and function.

The plasticity of new concrete permits the creation of limitless shapes, designs, and finishes.

Depending on the look that one desires and the type of concrete finish floor, specialized tools are used, which can turn any simple cement finish floor into gorgeous-looking flooring.

Benefits of concrete floor finish

In contrast to hardwood, laminates, ceramic tiles, and rubber, concrete finishes excel in durability and require minimal maintenance.

Ideal for high-traffic areas, concrete patio finishes provide customization options, various textures, colors, and designs. Besides, concrete flooring is favored in hot climates for its cooling properties, making it well-suited for temperate weather.

The concrete finishes also offer added functional benefits of durability, water resistance, and reduced slips and trips.

Finishes on concrete

These are the most common types of concrete finishes.

1. Trowel concrete finish

Trowel finish, known as the “smooth finish,” is the most basic level of concrete finishing. Still, these types of concrete floor finishes demand some amount of skill and precision in accomplishing a flaw-free, even, and blemish-free surface.

The working process involves thoroughly leveling, floating, and troweling wet concrete before it dries into a smooth, glossy texture.

Masons use tools such as screeds and trowels to create this finish.

Concrete screeds, usually of metal or wood, are dragged across the surface and then refined with a trowel to remove small blemishes.

On larger projects, a power trowel that looks a lot like a large fan blade is commonly used for efficiency.

Uses: Areas include indoor spaces, roof slabs, garages, utility areas, commercial areas, and walls.

Pros: Inexpensive, versatile, and faster to apply than other concrete finishes.

Cons: Not appropriate for outdoor areas. It is slippery when wet, and less attractive compared to other concrete finish options.

2. Stamped concrete finish

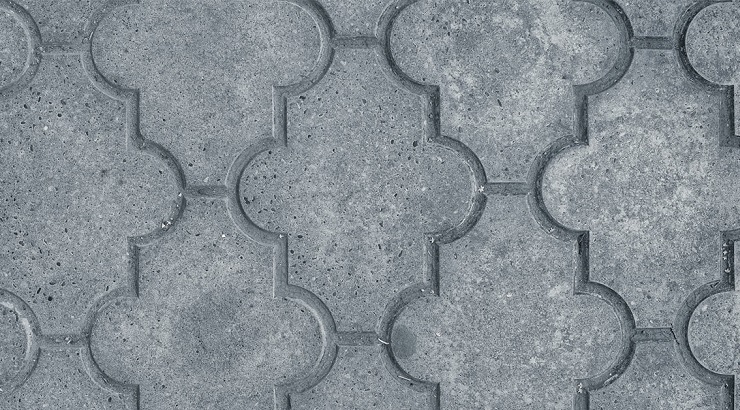

Also known as textured or imprinted concrete finishes, stamped concrete finish is a product of stamping a pattern on the just-levelled fresh concrete surface.

This decorative outdoor concrete finish brings innovation to many outdoor spaces. Stamped concrete finish is used mainly for flooring in driveways, walkways and patios.

This will require workers who have undergone specialized training and who have professional equipment for handling hardeners, release agents, and forms, among others.

Uses: Outdoor spaces, recreational areas, parks, patios, walkways, and landscaping.

Pros: It allows for unlimited customizations and designs that aim at achieving the desired look, thereby making decorations look very nice.

Cons: Etched designs may render the surface less durable and, therefore, prone to cracking and freezing.

3. Broom concrete finish

As the name implies, broom concrete finish is attained by moving a broom across newly poured concrete, making ridges in the process for the provision of traction control.

While less aesthetically pleasing compared to other finishes, these ridges introduce a non-slip surface, perfect for places like swimming pools and walkways, which are primarily considered for safety.

RELATED: How to Finish Concrete Floor in 7 Steps

Swirl finish is an advanced broom finish characterized by consistent swirled impressions, arc shapes, or geometric patterns created by the swirling of a broom.

You can vary the size of such ridges in these various concrete broom finishes by using bristles of variable dimensions.

Uses: Outdoor locations, driveways, walkways, parks, swimming pools, and patios.

Pros: Gives more traction; suitable for activities outdoors around areas with water.

Cons: Water and dirt collects between the ridges.

4. Polished concrete finish

A polished concrete finish is achieved by grinding and polishing a slab using particular machines with diamond abrasives and a chemical to gain the desired texture.

The process involves the usage of chemical hardeners and coatings to increase resistance to water, damage, and stains.

Polished concrete is a great choice for modern industrial-style interiors. In many applications, it’s used due to its beauty and durability.

Uses: Indoor spaces, expansive warehouses, retail stores, showrooms, office buildings, and residential areas.

Pros: It gives out a stylish, modern appearance, and the surface is very durable.

Cons: Not suitable for outdoor and high vehicular traffic areas.

5. Rock salt concrete finish

A salt concrete finish is attained by tamping in coarse rock salt into freshly poured concrete slabs with special rollers, which are then washed off later by a flood of water once the concrete has hardened.

RELATED: How to Check Quality of Cement

This sort of concrete finish will have a surface of small pitting, which assists in generating more friction hence creating a non-slip decorative surface, perfectly suited for pool decks.

Uses: pool decks, areas near water sources, large fountains.

Pros: Skid-resistant, enhances traction in water-adjacent areas, visually appealing, and budget-friendly.

Cons: Small pits may collect water, requiring proper sealing to prevent potential cracking.

6. Epoxy resin finish

Epoxy resin finishes are one of the more popular sealers for concrete surfaces.

Floor epoxy is a type of paint that is created from a liquid catalyst and hardener that are mixed just before application.

This mixture reacts chemically to give a finish that is high gloss, vibrant, and very resilient—therefore, suitable for high-traffic commercial applications.

Uses: Suitable for indoor spaces.

Pros: Provides wonderful aesthetics, with high durability and a luxurious appearance.

Cons: Very expensive and labor-intensive.

7. Stenciled concrete finish

Stenciled concrete finishes are somewhat similar to stamped finishes in the sense that they attempt to add some decorative appeal to the surface. However, they go about it differently.

As the term suggests, stencilled finishes use paper stencils as opposed to specialized stamps. This finish is relatively easier to lay and requires less skill.

It is achieved by laying a stencil on freshly poured concrete and gently working it into the surface. After partial curing, the stencil is lifted, revealing the design.

Common stencil patterns replicate the appearance of bricks, tiles, natural stones, geometric shapes, and cobblestones.

Uses: Interiors, patios, pathways, landscaping.

Pros: Cost-effective substitute for stamped concrete, imparts decorative flair to concrete surfaces.

Cons: Susceptible to cracking; lower durability.

8. Exposed aggregate finish

Exposed aggregate is a popular textured concrete finish achieved by washing or otherwise removing the top layer of freshly poured cement to expose coarse decorative aggregate.

This is in addition to the aesthetic value, where exposed aggregates offer increased friction, a feature that should be most welcome in outdoor spaces.

This finish comprises colored natural stones such as quartz, granite, basalt, and limestone, or materials like recycled glass or seashells to create finishes that can be visually pleasing.

Uses: Outdoor areas, driveways, walkways, parks, swimming pools, and patios.

Pros: Visually pleasing and provides nonskid properties, uniquely enhancing your outdoors.

Cons: More expensive compared with other types of finishes; prone to wear if not sealed well.

9. Swirl Finishes

These are some of the most brilliant kinds of concrete finishes obtained by spreading the concrete surface in a consistently overlapping circular pattern.

Swirl finish provides an excellent surface suitable for outdoors. These finishes offer a safer walk when compared with smooth concrete finishes, especially during the rainy season.

10. Colored finish

Coloring is an excellent method of finishing concrete surfaces, and it allows enormous scope for combinations of color and creative applications that can bring much life to concrete finishes.

Some colors—pigments—are mixed at the time of mixing the concrete, while other methods, such as staining, occur after the hardening of the concrete.

Uses: External and internal areas, commercial premises, industrial buildings, sports, and recreational facilities.

Pros: This has a large color palette and has low maintenance.

Cons: Colors will be faded due to the aging process of concrete. Plus, it takes quite a long time to apply and peels off in areas with heavy foot traffic.