Residential Projects

7 of the World’s Most Famous 3D Printed Homes

3D printing construction enables builders to make houses in a matter of hours.

3D construction printing technology is reshaping the construction industry, empowering builders to create 3D print homes in just 24 hours or thereabouts.

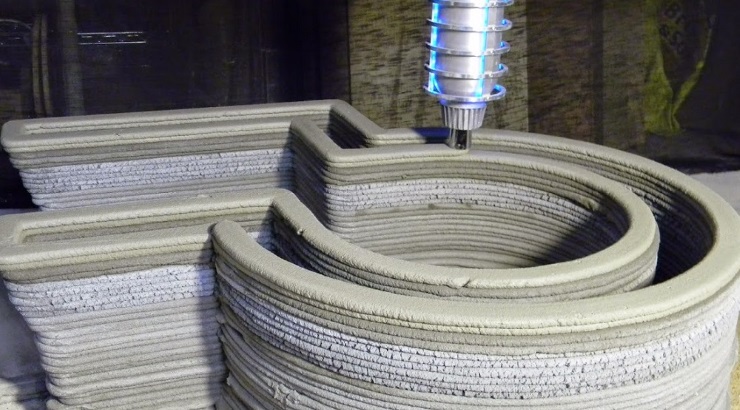

This technology uses giant 3D printers to spray layers of specially formulated materials, primarily consisting of concrete or polymers, to make components for house assembly.

What are 3D print homes?

3D printed houses are life-size homes built primarily with 3D printing technology. They can be built on-site or off-site in a matter of hours, offering significant cost savings.

Typically, featuring free-form, curvilinear shapes constructed from a cement mix, 3D-printed housing ranges from inhabitable beta prototypes under study to move-in-ready affordable housing and high-end luxury homes.

How 3D print houses are built

As stated above, 3D printing of homes is done using specialized printers that lay down layers of materials successively to build a complete project.

The printers move along a pre-determined path to place each layer of material, tracing outlines and pushing out material until the entire process is completed.

Thanks to advancements in 3D construction printing technology, it is now feasible to construct an entire house within an impressive timeframe of 24 hours.

Here are seven of the world’s finest 3D print homes.

1. Curve Appeal

Curve Appeal, the brainchild of Wimberly, Allison, Tong & Goo. (WATG), markets itself as the world-first freeform 3D-printed luxury home.

The 3D-printed home that is set to open this year in Chattanooga, Tennessee, is tipped to revolutionize the architecture, engineering and construction industry.

The project dates back to 2016 when architects in Chicago unveiled a design for a 3D-printed house made using plastic, carbon-fibre panels and glazed walls.

To overcome the limitations of traditional 3D printing, Curve Appeal uses robotics to generate customized shapes and curves, resulting in high-quality designs.

The Curve Appeal features a rock formation with a smooth concrete exterior, with four-sided archways supporting the exterior casing, replacing old-style walls and roofs.

2. Eindhoven

Eindhoven University of Technology developed a concept for what it called the ‘world’s first 3D-printed houses that people can live inside’.

RELATED: Inside the World’s Largest 3D-Printed House

The first of these proposed 3D-printed homes – a three-bedroom bungalow that looks like something you would find in outer space—was completed in 2021, in Meerhoven, west of the Dutch city of Eindhoven.

Eindhoven houses were built through a partnership between the university, the city municipality, contractor Van Wijnen, realtor Vesteda, materials maker Saint Gobain-Weber Beamix, and engineering firm Witteveen+Bos.

3. Gaia

Italian 3D-printing firm WASP produced tiny houses to show off the capabilities of their ground-breaking Crane WASP printer.

Dubbed Gaia, the 3D printed homes are 30 sq. metre dwellings with a 3D printed external shell and internal timber beams supporting each unit’s wooden roof.

RELATED: How Bentley Tower Miami Is Redefining City Living

In October 2018, WASP printed a house in the Italian region of Emilia-Romagna using a natural mud mixture made from soil taken from the surrounding site, and waste materials from rice production such as chopped straw and rice husks.

WASP claims that its 3D-printed homes are biodegradable.

4. New Story

New Story, an America-based non-profit, partnered with Texas tech firm ICON to build the world’s first 3D-printed village in Mexico as part of efforts to combat global homelessness.

Using a giant Vulcan II 3D printer, the two partners churned out the shells of each 500-square-foot house, with the roof, windows and interiors fitted later.

The 10-metre-long machine began at the base of the house, layering the concrete to the top of the building, where a roof was then fitted.

The entire process took about 24 hours per house.

With two bedrooms, a living room, a kitchen, and a bathroom, each of the 3D-printed homes can comfortably accommodate a small family.

5. Dus

In 2016, Dutch studio DUS Architects 3D printed an eight square metres cabin in Amsterdam that came with its internal bathtub among other features.

The architects used sustainable bio-plastic to create the 3D-printed urban cabin, to show how additive manufacturing can provide solutions for temporary housing, especially after natural disasters.

The cabin is fashioned in such a way that a window breaks one end while the other integrates both an entrance and a stepped porch balcony.

The walls of the structure are designed with protrusions that create a three-dimensional surface, giving the cabin additional structural firmness.

The cabin can be demolished, and the materials can be recycled when no longer needed.

RELATED: 3D Printing Technology for Construction

6. Mirreco

Perth-based biotech company Mirreco built several hemp-based 3D printed homes in Australia to harness the potential of industrial hemp.

Mirreco partnered with Arcforms, an architectural firm also based in Perth, to manufacture hemp panels that can be used in construction projects.

The panels can be produced straight through a 3D printer and then used to put up the structure of the house. Mirreco claims the panels are “easy to produce, and provide superior thermal performance.”

7. PassiveDom

PassiveDom House, created by PassivDom – a start-up based in Ukraine and California, is a 3D-printed home designed to run entirely on solar energy and to generate water from the atmosphere.

PassivDom claims they can 3D print the houses in just eight hours and that a house can be printed and delivered to the customer on the same day.

However, once the printing was accomplished, the house still required some finishing that could only be performed using traditional building methods.

In late 2019, PassivDom rebranded as Haus.me as it prepared to present a new international team and kick off in new countries.

The company, however, continues to operate under its old name in Ukraine.