Innovation

3D Printing Technology for Construction

Everything you need to know about 3D printing for construction.

Over the past few years, builders have been warming up to 3D printing construction technology as a solution to the challenges within the industry.

Also known as additive manufacturing, 3D printing for construction involves laying down layers of materials successively to build a complete project.

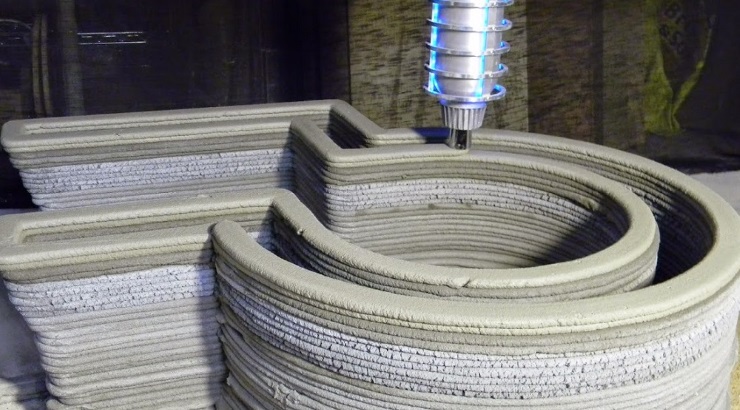

3D printing for buildings makes use of specially developed customized 3D printers to produce large-scale structures layer-by-layer using additive manufacturing methods.

A typical 3D printing construction project usually begins with a 3D digital model of the building to be constructed.

This model is virtually sliced into individual layers. Then, the printing robot or gantry system moves on a predetermined path to place each layer of material, tracing outlines, and extruding material until it’s all complete.

When one layer is done, it begins the creation of the successive layer on top of the previous, one until it completes the entire structure.

The materials used in shaping the 3D structures normally include concrete, metal, or polymers.

The most common 3D printing technique for building employs a robotic arm that places concrete while following a back-and-forth motion. Other techniques incorporate powder binding and additive welding.

Another process involves the fixation of powder layers to form the object of interest; this is referred to as power binding. In additive welding, the construction of layers through controlled welding processes allows customized and efficient construction.

Benefits of 3D printing in construction

Speedy construction: 3D printing technology enables the production of parts in just a few hours, which reduces the prototyping phase’s length.

Each stage of the design process happens more quickly and at a lower cost compared to the traditional machining method.

Thanks to the automation, or partial automation, of this technology, an entire structure can be completed in just a few days.

RELATED: US Firm Delivers World’s Largest 3D-Printed House

Apart from that, automated 3D construction printers can operate through the night or in bad weather, thus minimizing any downtime.

Fewer errors: 3D printing in construction reduces human errors in construction to a minimum, hence providing safer and quality structures.

The automation of 3D construction printers reduces the requirement for human labour; site workers are mainly needed to monitor the process.

Versatile designs: It allows for the construction of complex shapes and designs that, in most cases, cannot be established using the traditional method of construction.

Compared to traditional processes, which are almost addicted to working with standardized plans and templates, 3D construction printing offers the capability of coming up with customized solutions.

Waste reduction: Whereas construction sites are synonymous with the generation of a lot of waste, 3D printing technology only makes use of the integral material that is necessary for each part, and because of this, very little goes to waste.

Material recycling: The main advantages of using 3D construction printers are that they can make use of recycled materials, thereby reducing the building cost and carbon emissions resulting from material manufacturing processes.

Drawbacks of 3D printing in construction

Costly investment: Acquiring or leasing a 3D printer is quite expensive, especially when factoring in the logistics for transporting the printers to the site.

In addition to the cost of the printer, you also need to take into account the ongoing costs of materials and maintenance. These can make it difficult to justify the technology over traditional construction techniques.

Material constraints: 3D printing in construction is confined to a narrow selection of materials. This reduces the variety of structures that can be printed and their durability/lifetime.

3D printing construction is currently confined to a relatively narrow field of materials, mainly concrete, plastics, and composite-based materials.

RELATED: Icon’s 3D-Printed Village in Texas Set for Completion

A narrow spectrum of raw materials sets limits to the kinds of structures one might print and directly impacts their durability and lifespan.

Labour shortage: Knowledge and expertise related to building 3D printing are scarce resources in the construction market.

This scarcity poses a big problem that hinders the adoption of 3D printing technology in construction projects, thus impeding innovation in the industry.

Quality control: Despite the ability of 3D construction printing to form very complex structures and uncommon designs, quality is hard to maintain.

Unlike traditional construction where supervisors monitor the quality of work, 3D construction printing relies upon the precision of the printer.

Types of 3D printers

In construction, 3D printing technology generally falls into two categories: robotic arms and gantry-style setups. Each of these technologies is discussed below:

Robotic arm extruders

In this case, the computer-aided design software controls the giant 3D printer’s robotic arm to lay down precisely, in patterns, shapes, and thicknesses pre-specified by the designer.

RELATED: The World’s Finest 3D Printed Homes

Controlled by computer-aided design (CAD) software, the robotic arm of the 3D printer accurately deposits materials in specified patterns, shapes, and thicknesses.

Gantry system

This is a large-scale 3D construction printer using a gantry system to move the print head on the X, Y, and Z axes. These printers find favor with construction firms printing large structures and buildings.

Gantry 3D printers are much faster at printing an object in comparison to other 3D construction printers; therefore, they would work well with construction projects.

Even with their capabilities, stability is supposed to be one of the key selling points of 3D construction printers, along with their cost advantage over other printer types.